SPEAK TO ME

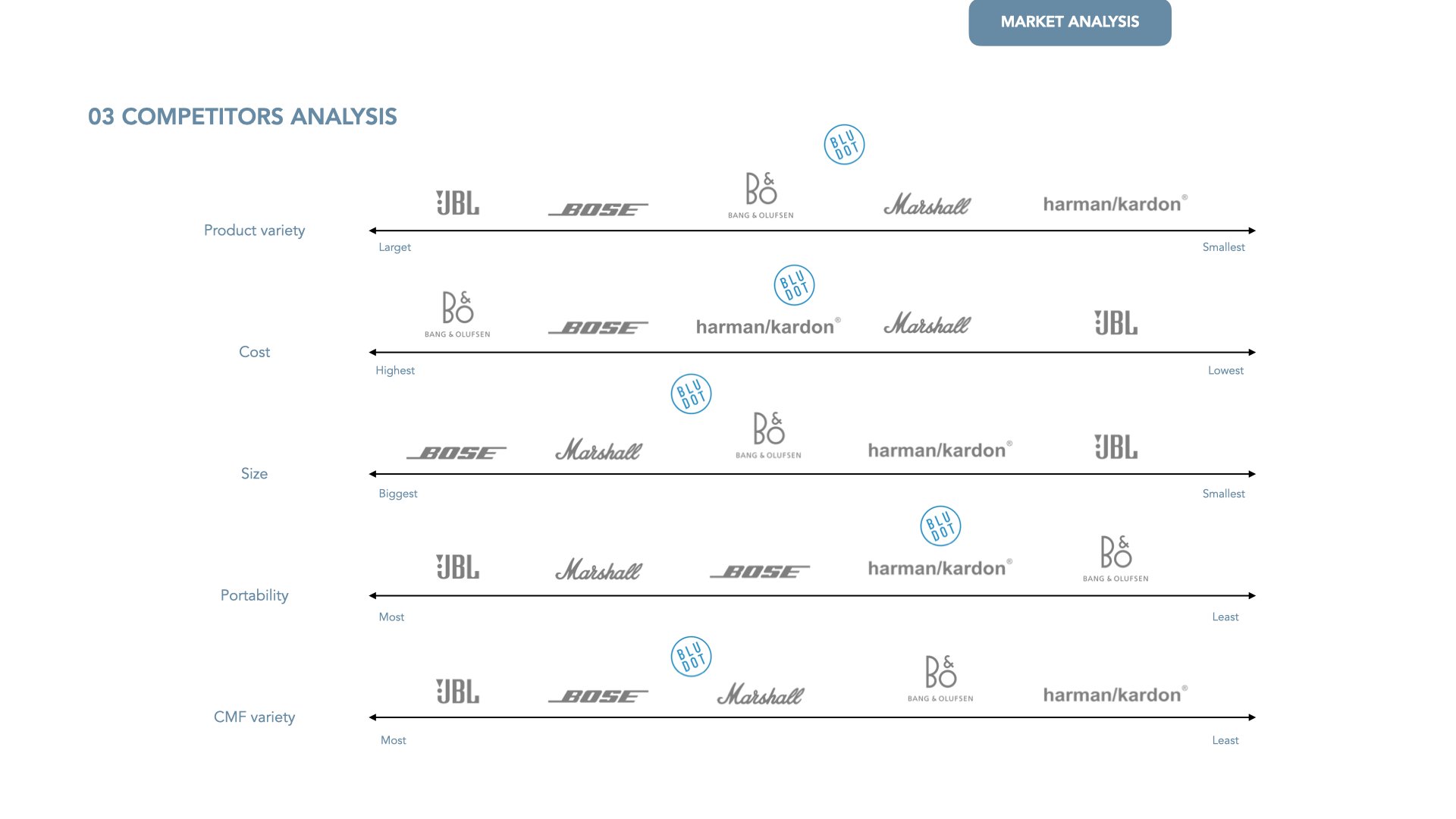

A brand-focused investigation to design and prototype a portable wireless speaker for a brand of your choice. The brand we chose to investigate was Blu Dot, a modern furniture brand based out of Minneapolis, USA.

We chose to design for Blu Dot, as we connected with their goals of sustainability as well as their meticulous design process.

The challenge of this project was to create a speaker that addresses the e-waste crisis which renders most electronics obsolete with the failure of one part.

TEAM

Raun Haji

Natalie Ferry

ADVISORS

Warren Young

Senior Designer, Blu Dot

Andrea Ruggiero

Studio Professor

CONTRIBUTION

Strategic Design Direction, User Research, Research Analysis, Prototyping, Product Development, Iterative Testing, Branding,

TIMELINE

Oct - Dec 2021

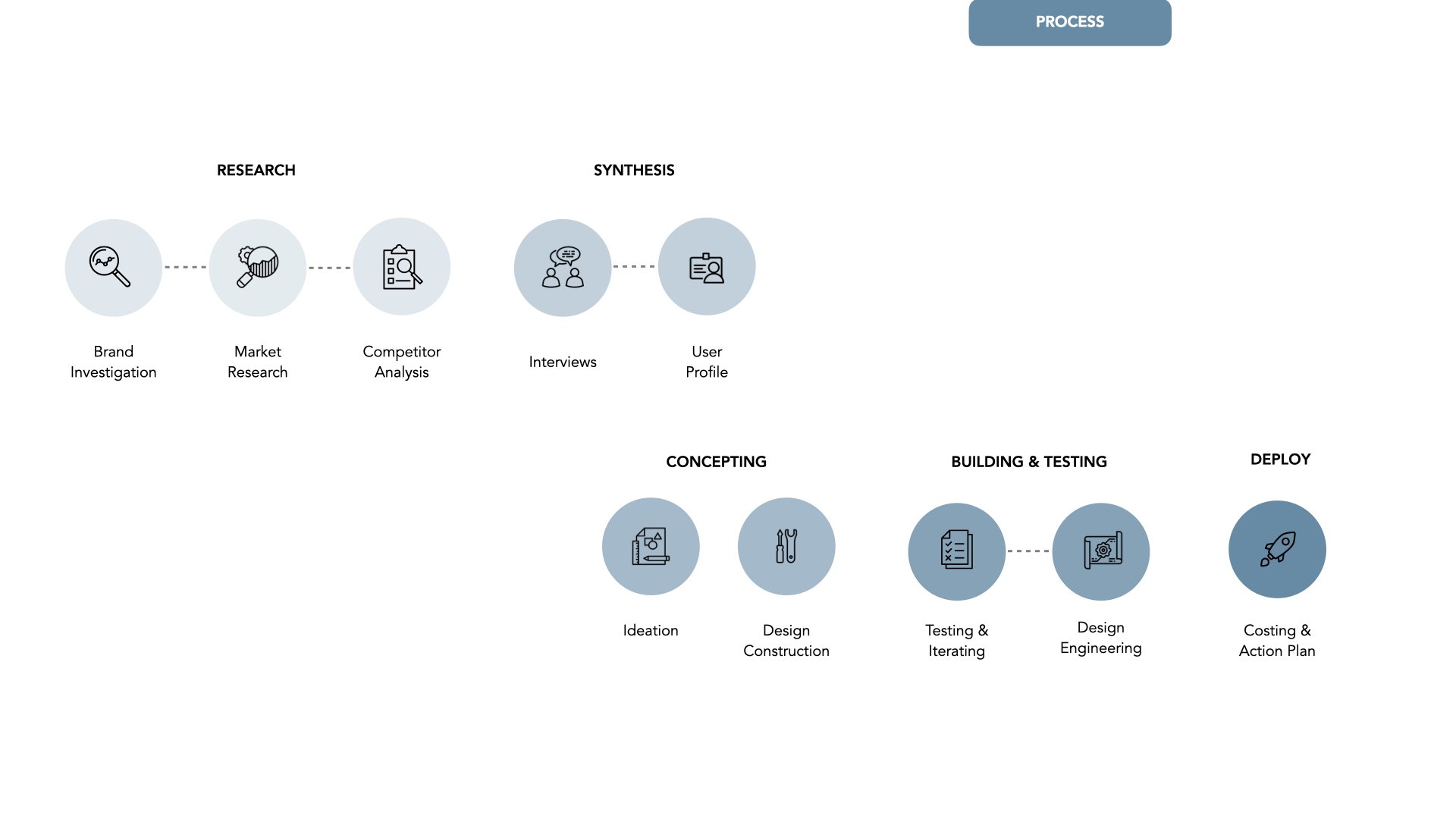

01 Brand Analysis

Most of Blu Dot’s early designs consisted of simple bent metal shapes which remains as an iconic part of the brand today.

Here’s a visual representation of Blu Dot today - while the brand has remained true to its origins, some things to notice are the bright colors, clean lines and innovative material uses like the bent steel and folded felt

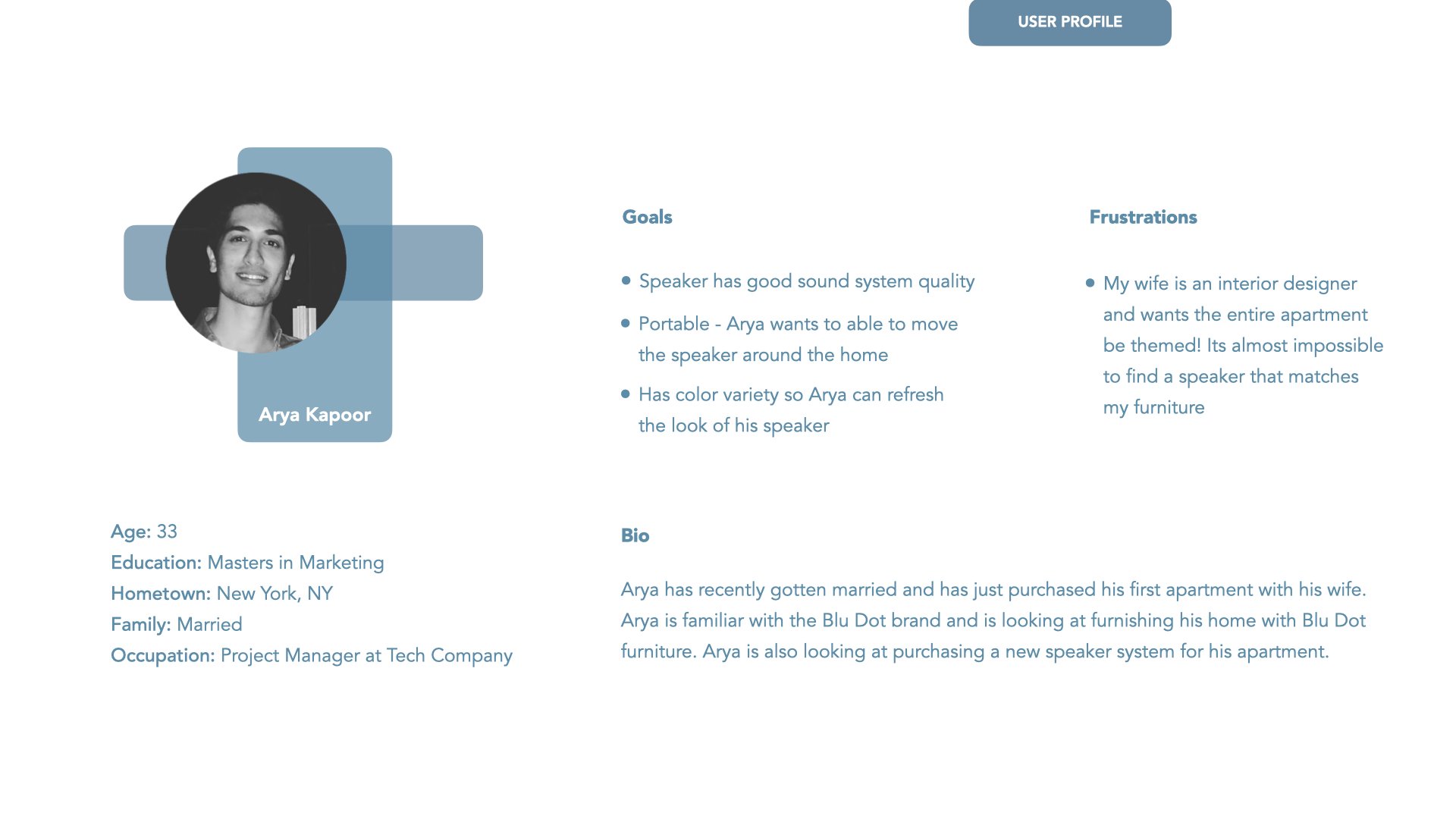

Blu Dot’s target audience is 30 to 50 year old urbanites who are looking to furnish their first or second homes with affordable yet timeless modern furniture

02 Concept Ideation

Our process began with sketching where we explored a wide range of ideas and took a lot of inspiration from existing manufacturing techniques used by Blu Dot. The sketches that consisted of perforated bent metal were the most successful in our opinion and we decided to use this iconic language in our later design.

We knew the form would ultimately follow the function, so it seemed fitting to take precedent from the gramophone, a classic design that is referenced throughout history. We decided to rethink this horn shape into something a bit more clean and modern.

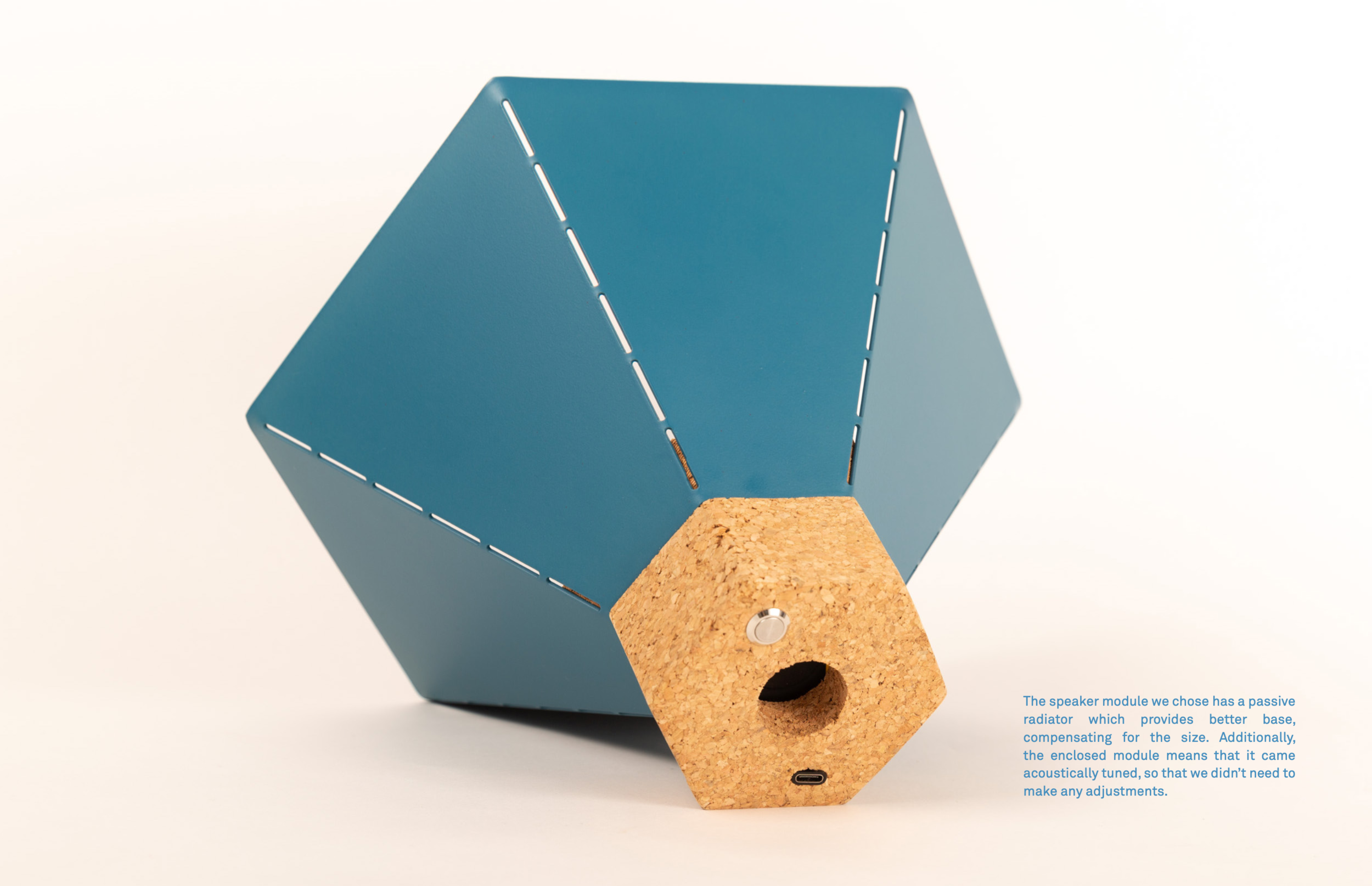

Above is the refined concept, a bent metal speaker with a cork housing to hold the speaker components. The shape is taking inspiration from the horn structure of the gramophone and is a modernized take on the timeless music device.

These are the early sketch models that we made by laser cutting chipboard and gluing the pieces together - experimenting with form and size. We also used these models to test the sound and see whether there would be any changes based on the number of sides, as well as the size of the cone.

From the sketch models we landed on this design which has 8 faces and a tapered cork base that would fit the speaker housing.

03 Concept Development

We had the opportunity to meet with Warren Young, a Senior Designer, who has been with Blu Dot for 17 years. During our conversation with him he mentioned that Blu Dot would likely use a simpler-6-sided shape and recommended that we explore a shift in form where two materials meet - which brings us to our final design (as seen on the right)

04 CMF

PERFORATED POWDER COATED STEEL

We decided to follow the perforation pattern and powder-coat the steel, so that the speaker would emulate Blu Dot’s iconic design language.

CORK

The addition of cork nicely contrasts the steel, and has wonderful versatility that makes it easy to machine and finish. Additionally, cork is a renewable material which was important to us as we strongly considered sustainability throughout the process.

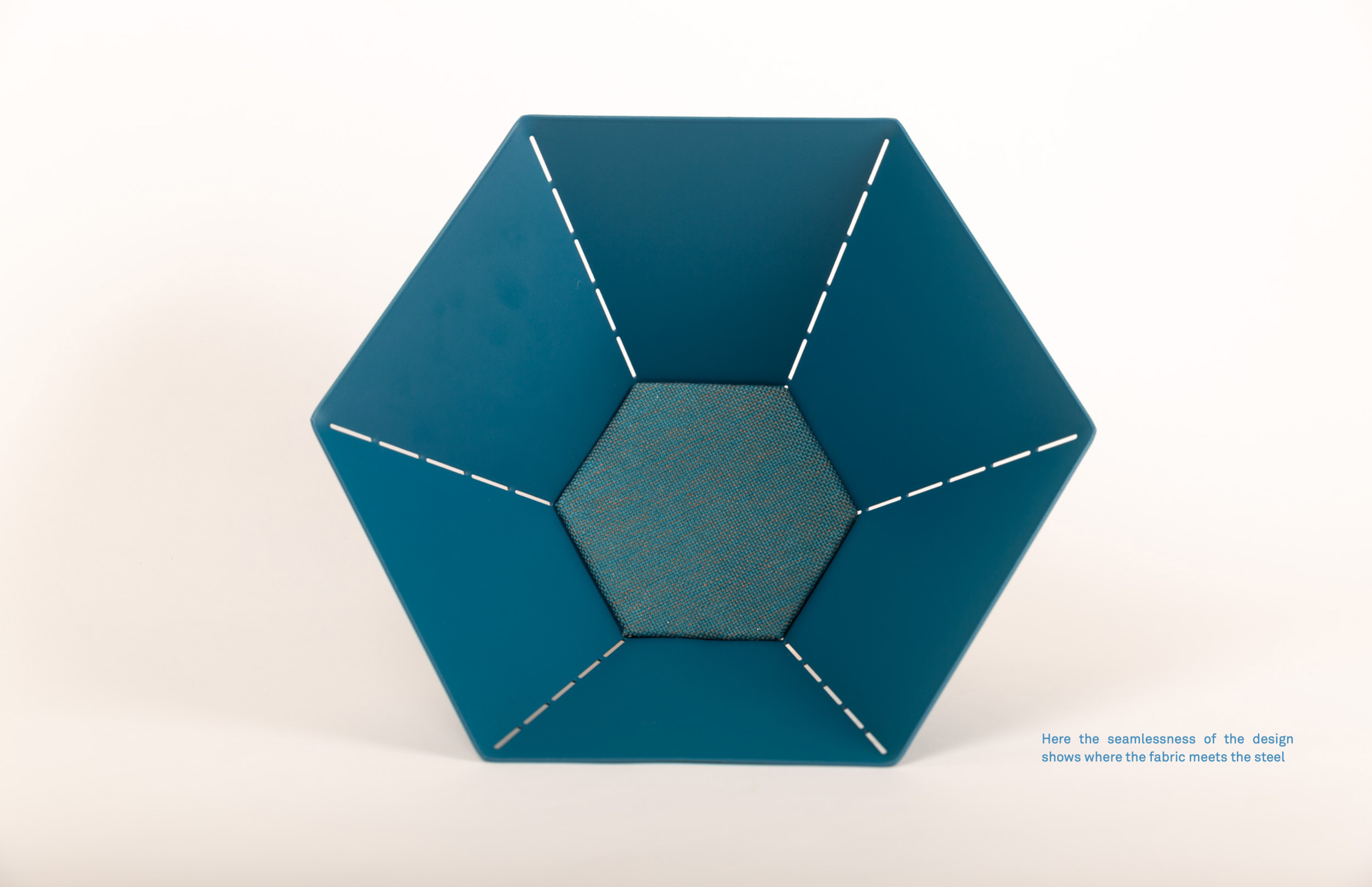

UPHOLSTERY FABRIC

Thinking back to sustainability statement made by Blu Dot we imagine that the fabric used for the speaker grill could be repurposed from the upholstery scrap produced from their furniture.

05 Technical Drawings

Here are the technical drawing of the cork housing - these were carefully designed to house all the electronic components

This technical drawing is of the bent steel component - the perforations remove the tension allowing it to be easily bent by hand

Paying close attention to the e-waste problem that the world currently faces we wanted to design a product that could easily be taken apart in order to access the electronics inside. The design uses only 4 screws to hold the inner and outer cork housing together, which sandwiches the steel cone in-between. This means that the consumer only needs a Phillips-head screw driver to access and replace any parts.

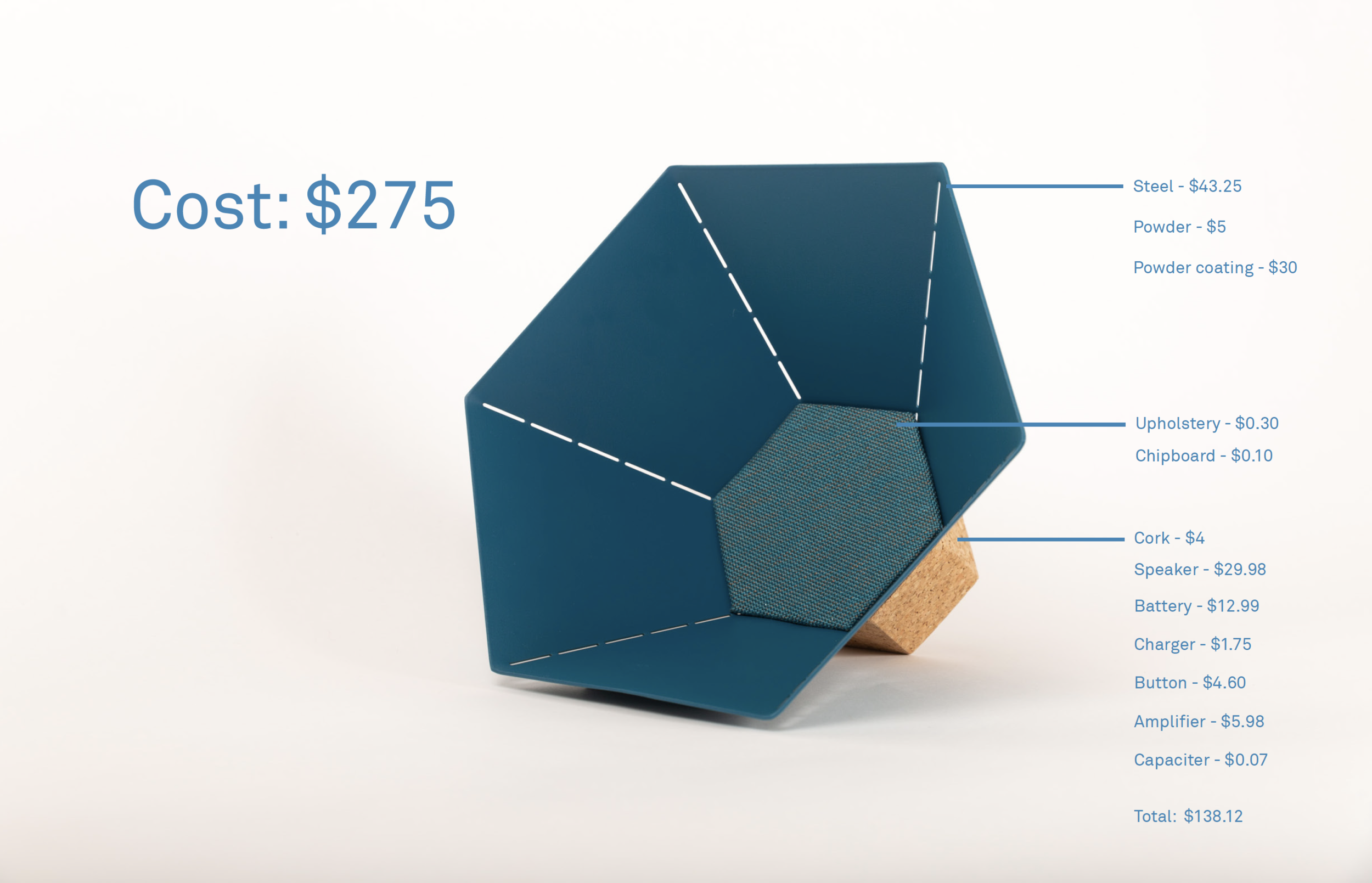

06 Costing

This initial cost analysis gives a basic breakdown on what each part cost. Given that in production these parts would be purchased in bulk the overall unit price would decrease. Currently we have an 80% markup which would set to increase upon mass production. Additionally, We used USB C which is an industry standard to avoid having to upgrade this part in the future. We also used tacks as the mechanism to hold the speaker grill in place, so that it can be easily pressed into the cork and changed out in the future to be refreshed with new colors if so desired.